Understanding Abrasives: Exploring Saint-Gobain's Flexovit and Norton Brands

|

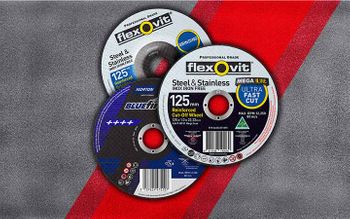

Abrasives, essential components of countless industries and DIY projects, play a vital role in grinding, cutting, polishing, and cleaning surfaces through friction. From sandpaper to diamond blades, each type of abrasive brings unique capabilities to the table, enabling users to achieve precision and excellence in their work. Among the variety of abrasive options available in the market, Saint-Gobain's Flexovit and Norton brands stand out as trusted choices for professionals and DIY enthusiasts alike. But what sets these brands apart, and why are they so well-known? |

|

Innovation and Excellence |

|

Saint-Gobain Abrasives' relentless pursuit of innovation through continual investment in research and development (R&D) is what sets it apart from the competition. By staying at the forefront of abrasive technology, Saint-Gobain ensures that its products remain ahead of the curve, delivering cutting-edge solutions that address evolving industry needs. This commitment to innovation and excellence has earned Flexovit and Norton brands a reputation for quality, reliability, and performance. |

Types of Abrasives Offered by Saint-Gobain |

|

For those seeking top-tier abrasives that deliver unmatched performance, durability, and value, Saint-Gobain's Flexovit and Norton brands represent the pinnacle of excellence in the industry.With a diverse range of products designed to meet the unique needs of professionals and DIY enthusiasts alike, Flexovit and Norton abrasives from Saint-Gobain are trusted companions in achieving perfection in every project. |

| Discover the extensive selection of Flexovit and Norton abrasives now available at our store. View Range |